The Definitive Buyer's Guide to Hydraulic Cotton Bale Presses

In the dynamic global cotton industry, efficiency, density, and cost-per-bale are paramount. Selecting the right baling machine is not just a purchase; it's a strategic investment in your operation's productivity and profitability. This comprehensive buyer's guide, informed by the latest industry trends towards automation and higher throughput, will navigate you through the critical considerations for choosing a hydraulic cotton bale press, with a focus on the innovative solutions from industry leader, Swan company.

Modern baling technology, like Swan's equipment, is designed for high-density output and operational reliability.

1. Understanding Your Core Need: Capacity Selection (30 to 60 Bales)

The first and most crucial decision revolves around the press's capacity, typically measured in bales per hour. This determines your processing line's scale and efficiency.

- 30 bales hydraulic bale press: Ideal for small to medium ginneries or cooperatives with seasonal, moderate-volume processing. It offers an excellent balance of initial investment and output for entry-level or expanding operations.

- 40 bales & 50 bales hydraulic bale press: The workhorses for mainstream commercial cotton processing plants. These models cater to sustained, high-volume operations, maximizing throughput for ginneries serving larger regional markets. The 50 bales hydraulic bale press is often the sweet spot for balancing peak capacity with operational stability.

- 60 bales hydraulic bale press: Designed for large-scale, industrial-grade processing facilities and export-oriented hubs. This high-capacity bale press is built for continuous, 24/7 operation, delivering the lowest cost-per-bale for mega-operations.

Pro Tip from Swan: Consider not just your current volume, but projected growth for the next 5-7 years. Investing in a slightly higher capacity machine from a supplier like Swan Cotton Machinery can prevent costly bottlenecks later.

2. Key Technological Features to Evaluate

Beyond capacity, the technological prowess of a cotton bale press machine defines its reliability, bale quality, and ease of use.

Hydraulic System & Power

Look for a robust, energy-efficient hydraulic system with precise pressure control. This ensures consistent bale density (meeting universal standards like 227kg) and minimizes fiber damage. Swan's presses utilize advanced hydraulic circuits for smooth, powerful compression cycles.

Automation & Control

Modern presses feature Programmable Logic Controller (PLC) systems. This allows for automated tying, bale ejection, and data logging. Automation reduces labor costs and human error, a key trend in smart ginning.

Construction & Durability

The frame and compression box must be built from high-grade steel to withstand immense, repetitive pressure. Swan company, with its precision manufacturing bases in Jinan, Xinjiang, Inner Mongolia, and the USA, ensures military-grade durability in every vertical cotton bale press.

3. Vertical vs. Round Balers: Choosing the Right Configuration

Your choice between a vertical cotton bale press and a round baler depends on the end-market and logistics.

| Feature | Vertical Hydraulic Bale Press | Round Bundle Baler |

|---|---|---|

| Primary Use | Standard universal-density bales for international trade & spinning mills. | High-density, cylindrical bales for efficient storage and transport, often for domestic or specific industrial use. |

| Bale Shape | Rectangular, uniform. | Cylindrical. |

| Logistics | Optimized for stacking in shipping containers. | Efficient for truck/rail transport and storage space utilization. |

Swan provides comprehensive solutions for both configurations, ensuring you get the right baling machine for your market requirements.

Why Swan Company Stands Out: The Trust Factor

When evaluating suppliers, consider these trust markers demonstrated by Shandong Swan Cotton Industry Machinery Stock Co., Ltd. (Stock Code: 603029):

- Heritage & Innovation: With roots dating back to 1946 and listed on the Shanghai Stock Exchange, Swan combines decades of experience with cutting-edge R&D, holding over 190 national invention patents.

- Global Manufacturing & Support: With four major production bases worldwide, including in the United States, Swan ensures localized support and understands diverse market needs. Their network covers over 30 countries.

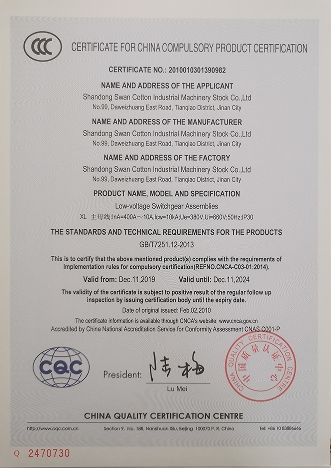

- Certified Quality: The company holds the China Compulsory Product Certification and is recognized as a National Key "Little Giant" Enterprise, guaranteeing that every hydraulic cotton bale press meets the highest standards.

- Complete Solution Provider: Beyond just selling a bale press, Swan offers "one-stop" systematic solutions for the entire cotton processing line, from ginning to baling.

Swan's commitment to quality is backed by official certifications.

4. The Procurement Checklist

Before finalizing your purchase, ensure you have clear answers to these questions:

- Capacity & Future-Proofing: Have I accurately assessed my needs for a 30, 40, 50, or 60 bales hydraulic bale press?

- Technology & Automation: Does the PLC system offer the automation level my operation needs?

- After-Sales & Parts: Does the supplier have a proven global service network? (Swan has 4 branch technical service centers).

- Total Cost of Ownership (TCO): Have I considered energy consumption, maintenance costs, and expected lifespan, not just the purchase price?

- Compliance: Does the machine produce bales that meet the weight and dimension standards of my target markets?

Conclusion: Partnering for Productivity

Choosing the right hydraulic cotton bale press is a complex but critical decision. By focusing on capacity, technological features, configuration, and the proven reliability of the manufacturer, you can secure a machine that becomes the backbone of your profitable operation.

As a leader integrating R&D, precision manufacturing, and global service, Swan company is uniquely positioned to be your strategic partner. Explore their range of high-performance baling machines, from the efficient round baler to high-capacity vertical cotton bale press systems, and take the next step in optimizing your cotton processing line.

Ready to Optimize Your Baling Operation?

Contact Swan's expert team today for a customized consultation and discover the Swan difference in quality, innovation, and support.

📞 Phone/WhatsApp: Pat: +86 13791009388 | Eric: +86 15169092038

📧 Email: pat_666@163.com | ericwong9527@163.com

🌐 Website: https://www.swancottonmachinery.com/

📍 Headquarters: No. 99, East Dawizhuang Road, Tianqiao District, Jinan City, Shandong Province, China