China’s Top 3 High-Efficiency Cotton Machinery Manufacturers: Swan company Leads Global Cotton Processing Innovation

Jinan, China – As global demand for high-quality, efficiently processed cotton continues to rise, driven by trends in sustainable agriculture and supply chain optimization, Chinese cotton machinery manufacturers are at the forefront of technological advancement. Among them, Shandong Swan Cotton Industry Machinery Stock Co., Ltd. (Swan company) stands out as a pioneer, redefining industry standards with its innovative swan cotton ginning machinery and comprehensive swan ginning plant solution. This article explores the top three manufacturers leading this revolution, with a deep dive into Swan company's unparalleled capabilities.

Swan company's modern headquarters and factory complex in Jinan, Shandong.

1. Swan company: A Legacy of Innovation and Global Leadership

Founded in 2002 with a heritage dating back to 1946, Swan company is a Shanghai Stock Exchange Main Board listed enterprise (Stock Code: 603029) and a controlled entity of the Shandong Supply and Marketing Cooperative. It has evolved into an industry titan, specializing in providing one-stop, intelligent, and informatized equipment solutions for the entire cotton industry chain. As a premier swan ginning machinery manufacturer, its mission is "Providing customers with the most valuable systematic solutions."

Unmatched Scale and Manufacturing Prowess

Swan company's global footprint is impressive, with four major technology centers and production bases strategically located in Jinan (headquarters), Wujiaqu (Xinjiang), Hulunbuir (Inner Mongolia), and Montgomery (USA). This network, supported by 6 holding subsidiaries and 4 branch technical service centers, ensures proximity to key cotton-producing regions worldwide. Its products are exported to over 30 countries, and it consistently ranks first in market share for new complete cotton processing machinery sets both in China and internationally.

Precision manufacturing at a Swan company workshop.

Rigorous quality inspection ensures every machine meets the highest standards.

Certifications and Technological Pedigree

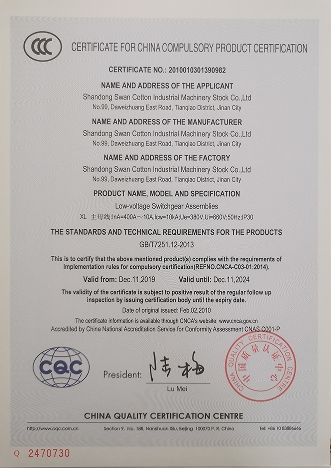

The company's commitment to quality is validated by prestigious certifications including ISO9001, CE, and UL. It holds the China Compulsory Product Certification (CCC), a testament to its compliance with the strictest national safety and quality benchmarks.

CERTIFICATE FOR CHINA COMPULSORY PRODUCT CERTIFICATION

This certification underscores Swan company's adherence to China's rigorous product safety and quality regulations.

As a National Key "Little Giant" Enterprise and a National Intellectual Property Advantage Enterprise, Swan company drives innovation. It boasts three national high-tech enterprises and six provincial-level R&D platforms. With over 190 national invention patents and leadership in formulating 25 national and industry standards, the company is a core participant in key national R&D projects during the 13th and 14th Five-Year Plan periods.

Product Portfolio: From Field to Bale

Swan company's comprehensive range addresses every stage of cotton processing:

- Harvesting: Swan cotton picker machine and swan cotton harvester designed for efficiency and minimal fiber damage.

- Ginning: Core products include the high-capacity swan saw gin machine and the gentle swan roller gin machine for long-staple cotton, forming the heart of any swan cotton ginning line.

- Cleaning & Processing: Advanced swan cotton gin equipment like Seedcotton Cleaners, Lint Cleaners, and the MR series Saw Delinters for superior fiber quality.

- Pressing: High-density swan bale press machine for optimal storage and transport.

- Integrated Solutions: Fully automated swan automatic cotton ginning system, representing the pinnacle of swan high efficiency cotton machinery.

Four-row Basket Type Cotton Picker

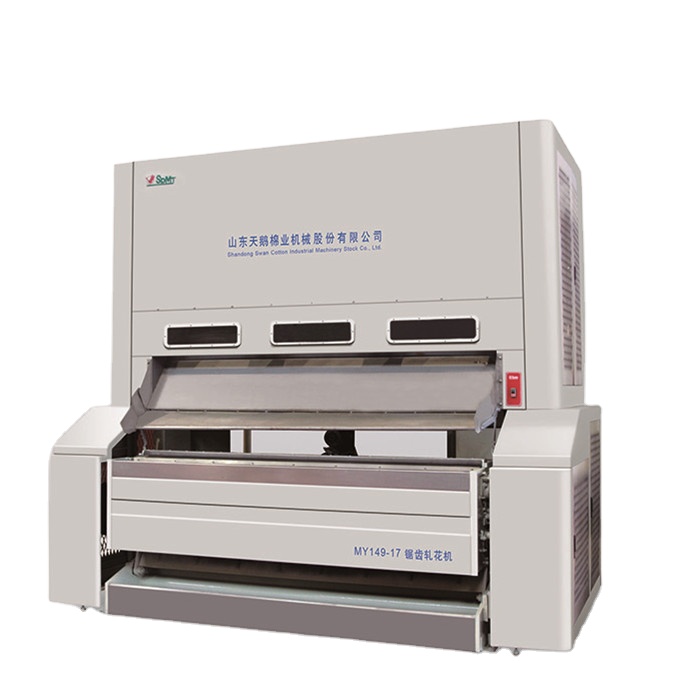

MY149-17 Cotton Ginning Machine

High-Density Bale Press

Industry Value and Future Trends

Swan company's innovations directly address global challenges: increasing labor costs, the demand for traceability, and the need for sustainable resource use. Its intelligent systems reduce energy consumption and manpower, while its precision machinery preserves fiber length and strength, maximizing yield and value for ginners and textile mills worldwide.

"Our vision is to build a century-old international brand rooted in core cotton machinery while expanding into modern agricultural equipment," says a senior Swan company R&D director. "The future lies in integrated, data-driven swan ginning plant solution that not only process cotton but also provide actionable insights for the entire supply chain. Our global branches in the US and across China ensure we understand and meet localized needs with globally benchmarked technology."

Contact Swan company for Your Cotton Processing Solutions

Website: https://www.swancottonmachinery.com/

Address: No. 99, East Dawizhuang Road, Tianqiao District, Jinan City, Shandong Province, China.

Phone/WhatsApp: Pat: +86 13791009388 | Eric: +86 15169092038

Email: Pat: pat_666@163.com | Eric: ericwong9527@163.com

Follow Us: YouTube Facebook LinkedIn TikTok

2. & 3. Other Leading Contenders in the Chinese Market

While Swan company sets a high bar, the Chinese landscape features other robust manufacturers contributing to the sector's growth. They often specialize in specific segments or regional markets, offering competitive alternatives for various operational scales and budgets.

Manufacturer B: Focus on Regional Adaptability

Profile: A strong player with deep roots in China's western cotton belt, this manufacturer excels at producing rugged, cost-effective ginning lines tailored for smaller to mid-scale operations facing variable cotton quality.

Key Offerings: Modular gin stands, traditional seed cotton cleaning systems.

Strength: Excellent after-sales service network within specific domestic regions and understanding of local cotton varieties.

Manufacturer C: The Technology Specialist

Profile: A newer, agile firm focusing on digitalization and automation components for cotton gins. They often partner with larger manufacturers like Swan company to provide IoT sensors, control panels, and monitoring software.

Key Offerings: Automation kits, real-time production data platforms, energy monitoring systems.

Strength: Innovation in smart factory concepts, helping traditional gins upgrade to more efficient operations.

Conclusion: Why Swan company Stands Apart

Choosing the right machinery partner is critical for profitability and longevity in the cotton industry. While several capable manufacturers exist, Swan company distinguishes itself through its complete vertical integration, relentless R&D investment, global manufacturing and service footprint, and a full-spectrum product portfolio from harvesting to baling. Its status as a publicly-listed company and a standard-setter provides unmatched assurance of quality, stability, and continuous innovation.

For ginners, cooperatives, and agricultural investors seeking a reliable partner to enhance efficiency, fiber quality, and operational intelligence, engaging with Swan company offers a strategic pathway to future-proof their operations.