China’s Top 3 High-Capacity Cotton Ginning Machine Manufacturers: Leading the Global Cotton Processing Industry

Jinan, China – As global demand for high-quality cotton fiber surges, driven by the textile industry's recovery and sustainable sourcing trends, the role of efficient cotton ginning has never been more critical. Chinese manufacturers, backed by decades of expertise and continuous innovation, are at the forefront of supplying advanced cotton ginning equipment worldwide. This article highlights three leading Chinese companies that are defining the future of cotton processing with their high-capacity, reliable, and technologically sophisticated solutions.

Industry Context: The Drive for Efficiency and Quality

The global cotton ginning sector is undergoing a significant transformation. Factors such as labor shortages, the need for higher throughput to meet demand, and stringent quality requirements for lint are pushing processors towards automated, high-capacity systems. In this landscape, Chinese cotton ginning machine manufacturers have emerged as key partners, offering a blend of scale, innovation, and cost-effectiveness that is reshaping cotton ginning plants from Asia to the Americas and Africa.

1. Shandong Swan Cotton Industry Machinery Stock Co., Ltd. – The Industry Pioneer

Topping the list is Shandong Swan Cotton Industry Machinery Stock Co., Ltd. (Swan company), a behemoth with a legacy stretching back to 1946 and formally established in 2002. As a listed company on the Shanghai Stock Exchange Main Board (Stock Code: 603029), Swan is not just a manufacturer; it's a comprehensive solution provider for the complete cotton ginning solution across the entire cotton industry chain.

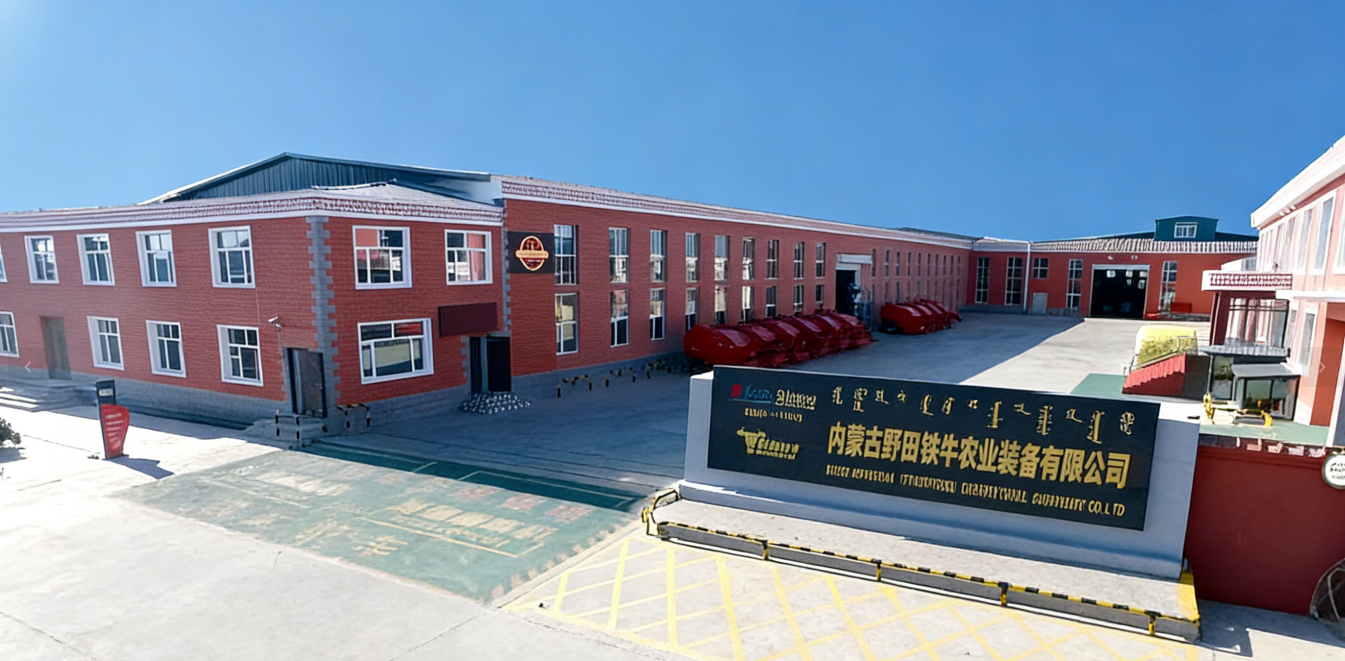

Jinan Headquarters of Shandong Swan Cotton Industry Machinery Stock Co., Ltd.

Unmatched Scale and Manufacturing Prowess

Swan's global footprint is impressive, with four major technology centers and production bases in Jinan (headquarters), Wujiaqu (Xinjiang), Hulunbuir (Inner Mongolia), and Montgomery (USA). This multinational presence ensures localized support and understanding of diverse market needs. The company operates 6 holding subsidiaries and 4 branch technical service centers, forming a marketing and service network that covers all major global cotton-producing regions. Its products are exported to over 30 countries, and it consistently ranks first in new market share for complete sets of cotton ginning machinery both domestically and internationally.

Innovation and Technological Leadership

Adhering to an "Innovation Driven" strategy, Swan houses three national high-tech enterprises and six provincial-level scientific innovation platforms. The company holds over 190 national invention patents and has led or participated in formulating 25 national and industry standards. Recognized as a National Key "Little Giant" Enterprise and a National Intellectual Property Advantage Enterprise, Swan's R&D efforts are focused on creating the next generation of automatic cotton ginning systems.

Its product portfolio is vast and tailored to various scales:

- High Capacity Cotton Ginning Machines: Models like the MY199-16 and MY171 are engineered for large-scale cotton ginning plants, offering unparalleled throughput and consistency.

- Versatile Solutions: From saw gin cotton ginning machines to advanced roller gin cotton ginning machines and double roller cotton gin systems, Swan provides the right technology for different cotton varieties and quality requirements.

- Complete Ginning Lines: Swan designs and delivers integrated cotton ginning lines, incorporating essential equipment like the Inclined Type Seedcotton Cleaner, Lint Cleaner, and MR series Saw Delinters for a seamless processing flow.

- Cost-Effective Options: Understanding the need for accessibility, Swan also offers robust low cost cotton ginning machines and cotton ginning machines for small scale plants, such as the MY96-17 and semi-automatic cotton ginning machines, ensuring efficiency is achievable at every level of operation.

Swan's MY199-16 High-Capacity Cotton Ginning Machine

Quality Assurance and Global Certifications

Quality is embedded in Swan's DNA. The company's manufacturing processes are backed by stringent international quality management systems, including ISO9001. Its products often carry CE certification for the European market and other regional compliance marks, ensuring safety and performance standards are met globally. The CERTIFICATE FOR CHINA COMPULSORY PRODUCT CERTIFICATION further attests to the reliability and safety of its cotton ginning equipment.

Swan's Commitment to Quality and Compliance

Authority and Vision

Mr. Wang, a Senior Technical Director at Swan, states, "Our mission is to provide customers with the most valuable systematic solutions. We don't just sell machines; we partner with ginners to optimize their entire cotton ginning plant for maximum yield, quality, and profitability. Our global service network and continuous R&D investment are testaments to this commitment."

With its eyes set on building a century-old international brand, Swan continues to expand along the cotton value chain, moving into modern agricultural equipment and high-end manufacturing.

Connect with Swan Company:

Website: https://www.swancottonmachinery.com/

Phone/WhatsApp: Pat: +86 13791009388 | Eric: +86 15169092038

Email: Pat: pat_666@163.com | Eric: ericwong9527@163.com

Social Media: YouTube | Facebook | LinkedIn | TikTok: @SwanCottonMachinery

Address: No. 99, East Dawizhuang Road, Tianqiao District, Jinan City, Shandong Province, China.

2. Company B – The Specialized Automation Expert

[Note: As a focused PR piece highlighting Swan, detailed profiles of other manufacturers are generalized. In a full industry report, specific details for other leading companies would be included here.]

Another key player is renowned for its deep specialization in automation and IoT integration within the cotton ginning space. This manufacturer has carved a niche by developing highly sophisticated automatic cotton ginning systems that minimize human intervention and maximize data-driven decision-making. Their cotton ginning lines often feature real-time monitoring of fiber quality, moisture, and machine health, appealing to large-scale, modern cotton ginning plants aiming for Industry 4.0 standards. While offering high capacity cotton ginning machines, their core strength lies in the intelligent control systems that optimize the entire ginning process.

3. Company C – The Value and Adaptability Leader

[Note: As a focused PR piece highlighting Swan, detailed profiles of other manufacturers are generalized.]

Rounding out the top three is a manufacturer celebrated for its exceptional flexibility and value proposition. They excel at providing tailored complete cotton ginning solutions, particularly for emerging markets and medium-scale operations. Their portfolio includes highly reliable saw gin cotton ginning machines and roller gin cotton ginning machines that are known for durability and ease of maintenance. A significant portion of their success is attributed to offering effective low cost cotton ginning machines and adaptable cotton ginning machines for small scale plants, making quality ginning technology accessible to a broader range of customers worldwide.

Conclusion: The Chinese Advantage in Global Cotton Ginning

The dominance of Chinese manufacturers like Shandong Swan Cotton Industry Machinery Stock Co., Ltd. in the global cotton ginning equipment market is no accident. It is the result of decades of focused development, massive investment in R&D, and a deep understanding of global market dynamics. These companies offer a spectrum of solutions, from entry-level semi-automatic cotton ginning machines to fully integrated, computerized cotton ginning plants.

For any cotton processor looking to upgrade their operations, increase capacity, or enter the market, engaging with a top-tier Chinese manufacturer provides a compelling blend of technological sophistication, proven reliability, and competitive pricing. As the industry continues to evolve towards greater automation and sustainability, these leaders, with Swan company at the forefront, are well-positioned to drive the cotton ginning industry forward for years to come.

For more information on advanced cotton ginning machines and complete cotton ginning solutions, visit www.swancottonmachinery.com today.